CIVIL ENGINEERING

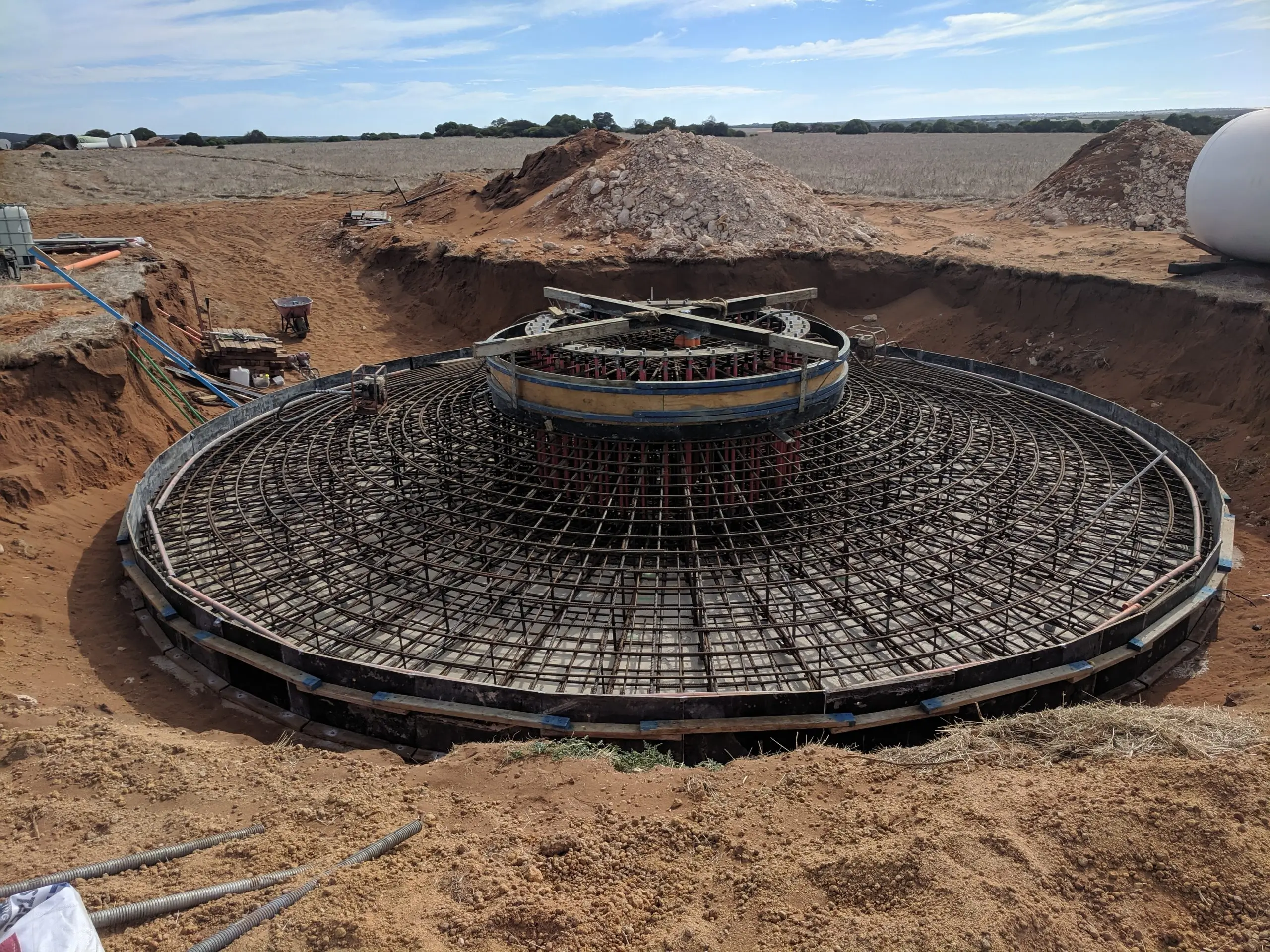

Our team is experienced in delivering design, engineering, project management or superintendence and have extensive expertise and experience in delivering high quality outcomes for a variety of Civil projects.

Our team is experienced in delivering design, engineering, project management or superintendence and have extensive expertise and experience in delivering high quality outcomes for a variety of Civil projects.

Our Structural Team offers a range of engineering, design, temporary works, or project management services in the infrastructure and renewable energy sectors, low-rise commercial, industrial structures and institutional buildings.

Our highly skilled mechanical team offer detailed design, drafting, engineering verification and design for Tanks, Vessels, Piping or even heavy earthmoving equipment.

McDowall Affleck is experienced liaise with key stakeholders across development plans, providing detailed construction cost estimates, design and documentation of all civil works, seeking tenders from suitable contractors, superintendence in accordance to various Australian standards on a variety of Land Development projects.

Unit 3, 28 Belmont Ave,

Rivervale, WA 6103